Casting resins, varnishes and

casting compounds for electrical insulation

This also protects them from external influences such as moisture, dust and chemicals. This gives the workpieces a longer service life - the windings can withstand the forces generated during operation. The casting resins also increase thermal conductivity and provide electrical insulation.

Coatings from selected suppliers - for the sake of our employees and the environment

SynFlex relies on particularly compatible coatings to protect employees and the environment. This is precisely why our impregnating agents - impregnating, trickling and casting resins, current UV resins, top coats and sprays as well as impregnating paints with water as a solvent - are environmentally friendly, low-emission and solvent-free. They have a low odour and are pleasant to work with.

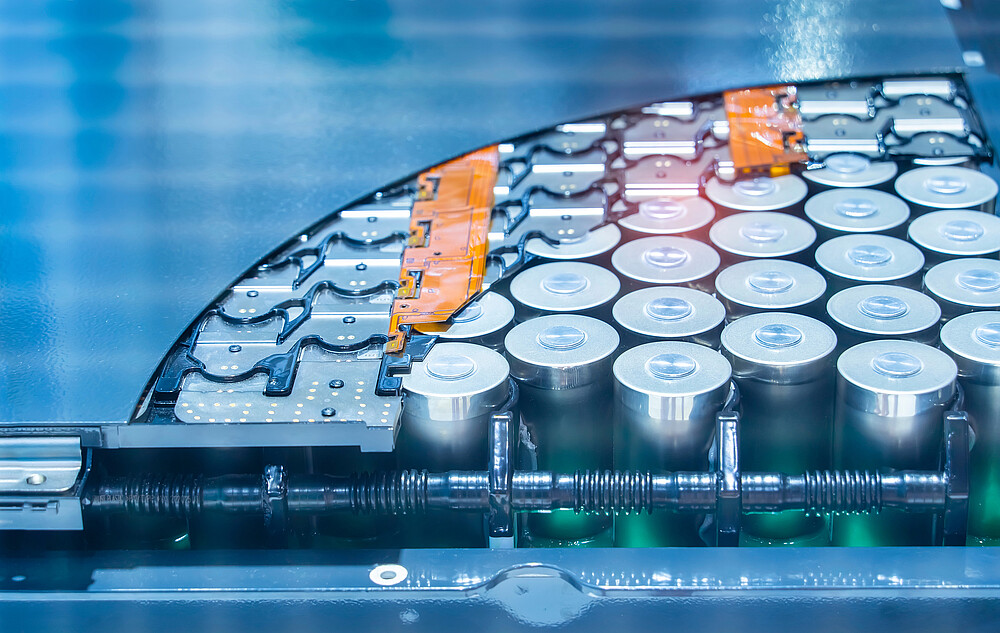

Casting resins and potting compounds in use

Our potting compounds are used throughout the electrical industry, including in electric motors, transformers and generators, household appliances and power tools. The automotive industry has also recognised their benefits.

Our impregnating agents from temperature classes Y 90 °C to C 220 °C are suitable for various impregnation processes. Contact us - we will find the right product for you.

Do you have any questions about our products and would like to send us an enquiry?

Our product manager will be happy to help you.

The right impregnating agent for your application

Impregnating resins

Impregnating resins can be divided into two groups: Dipping resin and trickling resin.

Immersion resin is used in an immersion process, i.e. the object to be impregnated is immersed in a tank of resin. A distinction is made between simple dipping and dipping combined with a current UV, roll-through, vacuum or VPI process.

In the trickle process, the material is applied drop by drop to the coils and the workpiece. The main advantage of this process is that less material is required. Our impregnating resins cover various requirements, as we offer them in different viscosities and with different bases.

Casting resins

Casting resins, also known as potting compounds, are used to seal and fill cavities - in sensitive electronics, coils and circuits. The casting resins in our range are based on epoxies, polyurethanes and silicones and vary in hardness (Shore hardness). Some of them are flame-retardant in accordance with UL 94. We also offer gap fillers and gels in the area of silicone-based potting compounds.

Coating varnishes

The coating lacquers from our company are available in different colours and are based on organic solvents or water.

WEVOSIL silicone potting compounds for superior thermal management and electrical insulation

Silicone-based potting compounds offer optimum protection for electronic components and can withstand even extreme conditions. WEVOSIL potting compounds are highly temperature-resistant and offer high mechanical and chemical resistance combined with excellent elasticity. We supply WEVOSIL potting compounds, gels, coatings, and gap fillers.

Product programme

SynChem| Product | Heat class | Type | Backing / Material | UL |

|---|---|---|---|---|

| Voltatex® 4201 1-component-resin | R / 220 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Voltatex® 4250 1-component-resin | R / 220 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Dolphon® XL-2109 1K Resin | H / 180 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Voltatex® 4200 1-component-resin | R / 220 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Voltatex® 4230 1-component-resin | R / 220 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Synthite AC-41 Polyurethane varnish | H / 180 °C | Finishing varnish | Polyurethane | Yes |

| Synthite ER-41 Polyurethane enamel varnish | H / 180 °C | Finishing varnish | Polyurethane | Yes |

| Synthite AC-43 Air drying varnish | H / 180 °C | Finishing varnish | Polyester | Yes |

| Synthite EB-43/387-D Polyester enamel varnish | H / 180 °C | Finishing varnish | Polyester | Yes |

| Voltacast 3100 Polyurethane casting resin | E / 120 °C | Casting resin | Polyurethane | Yes |

| Voltacast 3110 Polyurethane casting resin | E / 120 °C | Casting resin | Polyurethane | Yes |

| Voltacast 3200 Polyurethane casting resin | B / 130 °C | Casting resin | Polyurethane | Yes |

| Voltacast 3210 Polyurethane casting resin | B / 130 °C | Casting resin | Polyurethane | Yes |

| Dolphon® XL-2102 1K Resin | H / 180 °C | Dipping resin | Polyester | Yes |

| Dolphon® XL-2102 OPT 1K Resin | H / 180 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Dolphon® XL-2103 1K Resin | H / 180 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Voltatex ® 4020 1-component resin | N / 200 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Voltatex® 4100 1-component-resin | H / 180 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Voltatex ® 4130 1-component-resin | H / 180 °C | Dipping resin | unsaturated Polyesterimide | Yes |

| Voltatex® T050 Cleaning agent | Cleaning agent/thinner | |||

| AQUA-THERM BC-380/870-D | H / 180 °C | Yes | ||

| WEVOPUR 390 PU encapsulating system | B / 130 °C | Casting resin | Polyurethane | Yes |

| WEVOPUR 403 FL PU encapsulating system | F / 155 °C | Casting resin | Polyurethane | Yes |

| WEVOPUR 7210 FL PU encapsulating system | B / 130 °C | Casting resin | Polyurethane | Yes |

| WEVOPUR 552 FL PU encapsulating system | B / 130 °C | Casting resin | Polyurethane | Yes |

| Dolphon® XL-2112 single-component resin | H / 180 °C | Dipping resin, Trickling resin | unsaturated Polyesterimide | Yes |

| Voltatex® 4204 1-component impregnating resin | H / 180 °C | Dipping resin, Trickling resin | unsaturated Polyesterimide | Yes |

| Damisol® 3418 API 1-component-resin | N / 200 °C | Dipping resin | Epoxide | |

| Damisol® 3500 LoV 1-component-resin | H / 180 °C | Dipping resin | Epoxide | Yes |

| Voltatex® 2100 Impregnating varnish | H / 180 °C | Impregnating varnish | ||

| Voltahyd® 2220 Polyacrylate Coating Varnish | Finishing varnish | Polyacrylate | No | |

| WEVOSIL 22006 FL | H / 180 °C | Casting resin | Silicone | Yes |

| WEVOSIL 22027 FL | H / 180 °C | Casting resin | Silicone | No |

| WEVOSIL 22066 FL | H / 180 °C | Casting resin | Silicone | No |

| WEVOSIL 26040 FL | N / 200 °C | Casting resin | Silicone | No |

| WEVOSIL 20201/60 Gel | H / 180 °C | Casting resin | Silicone | No |