Your specialist for punched, bent and formed parts that are designed according to your individual requirements and that can be used in a wide range of industries. With our portfolio of punched and formed parts, we not only offer components, but also solutions for complex requirements in various application areas. From the automotive industry to the electrical and electronics industry, medical and shielding technology to communication and information technology - our punched and formed parts fulfil important functions in numerous key areas.

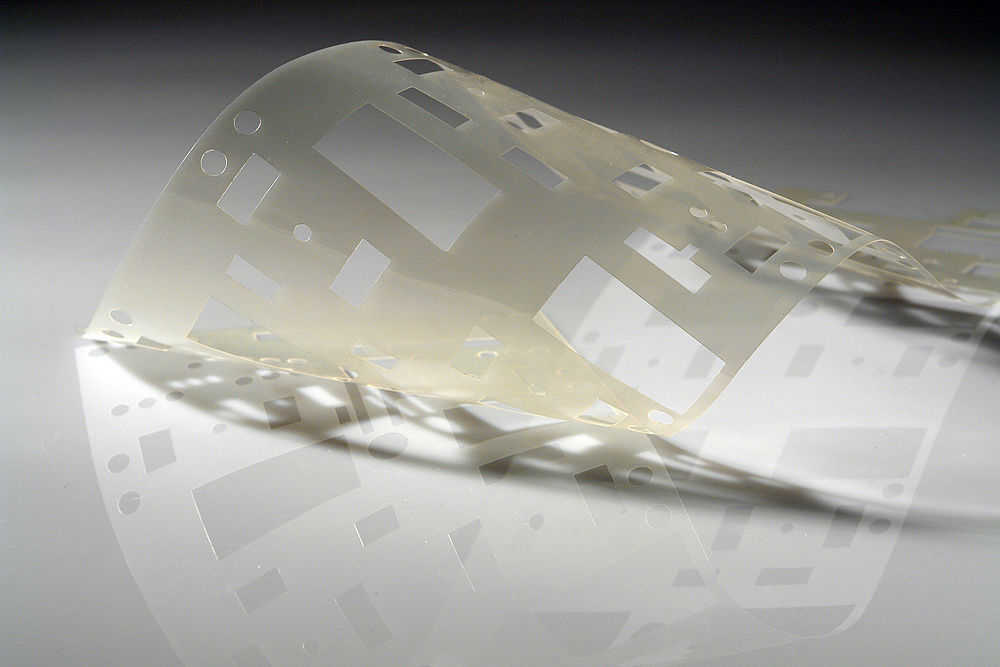

- As a system provider for the electrical insulation system, we specialize in technically sophisticated, high-quality materials such as polyester films, PI films, aramid papers or corresponding laminates. We also offer a wide range of other materials such as metal foils, non-wovens and other materials.

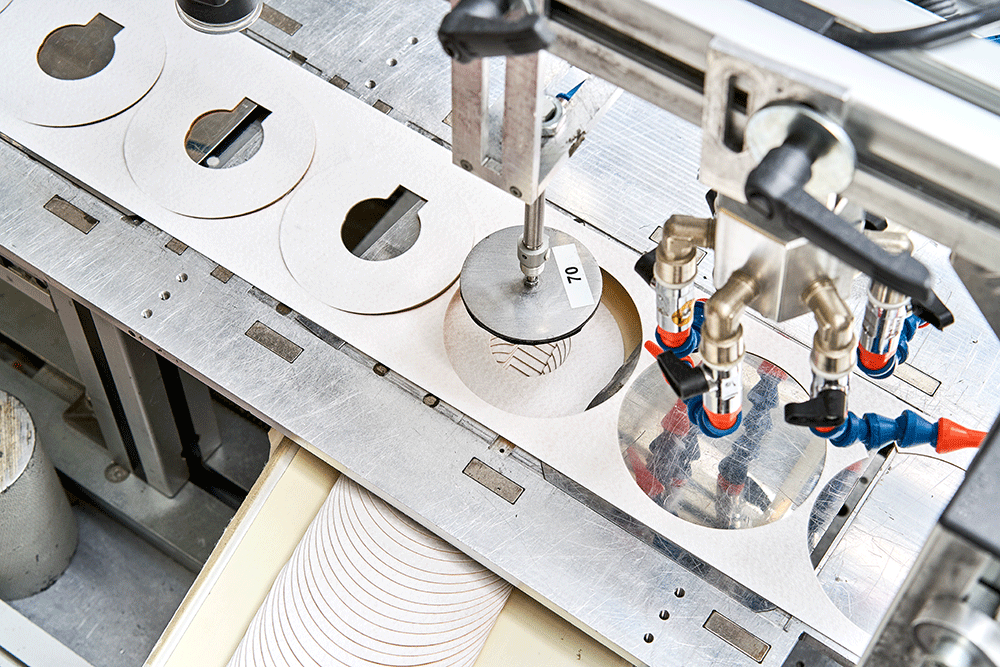

- Our large-scale machinery enables us to economically produce die-cut parts from quantities of 1 to millions.

- At our competence center and production site in Schramberg, we have pooled our decades of expertise in the manufacture of punched, bent and formed parts for you.

- You benefit from our wide range of materials available immediately from stock, which guarantees flexibility and efficiency for your project.

Our promise in terms of performance

The 9 advantages of our die-cut parts portfolio summarized for you:

Wide range of die-cut parts

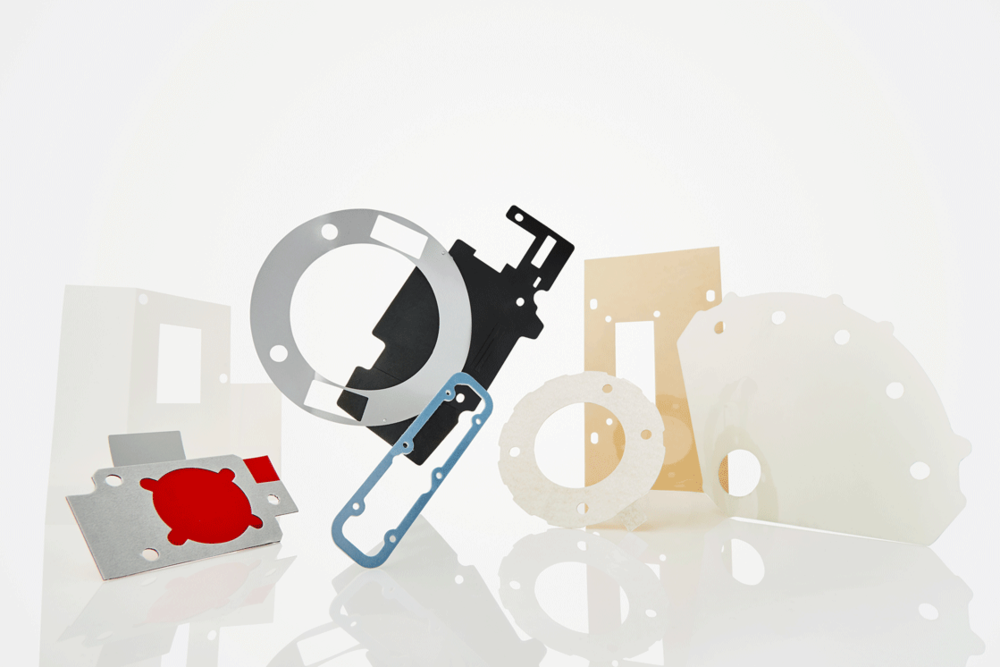

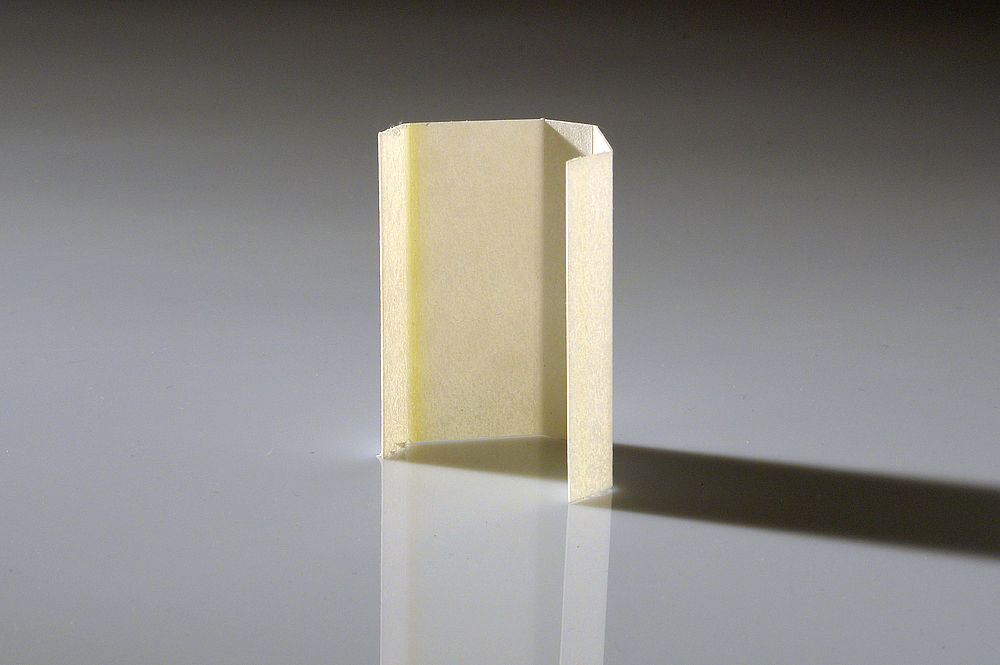

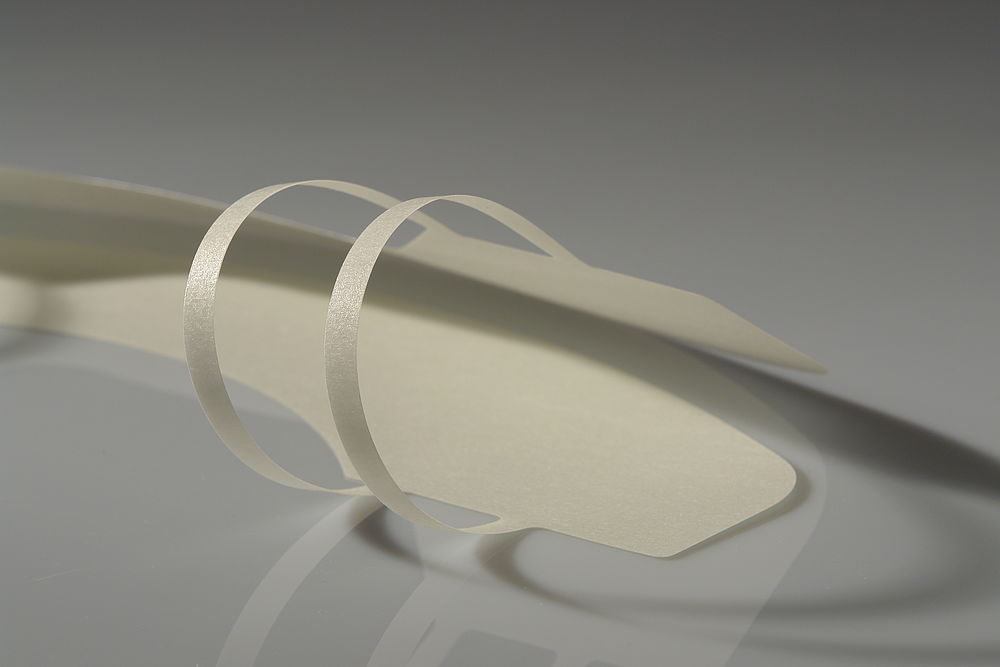

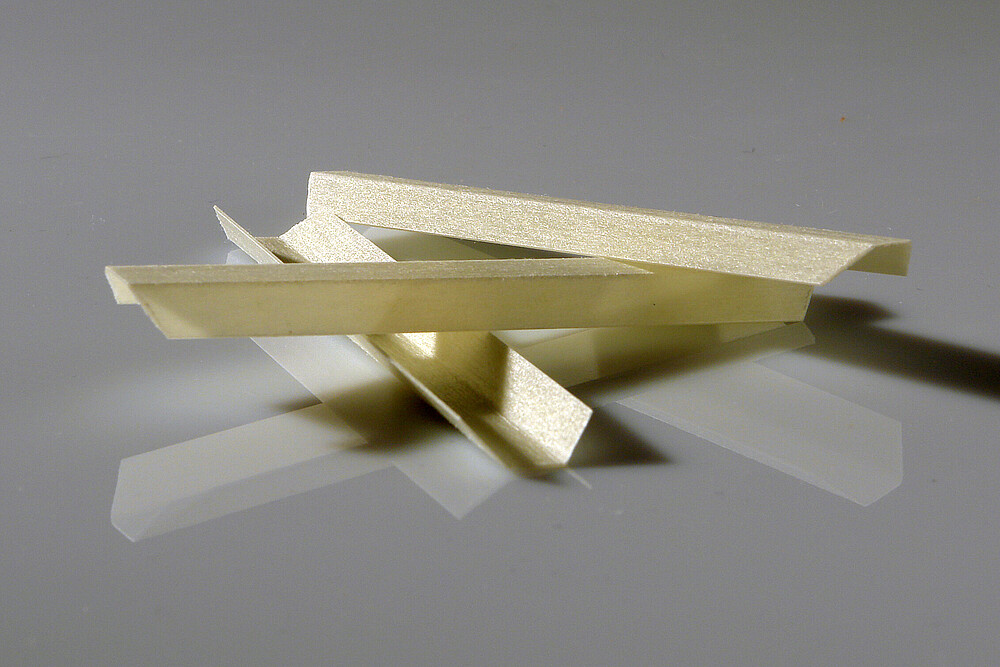

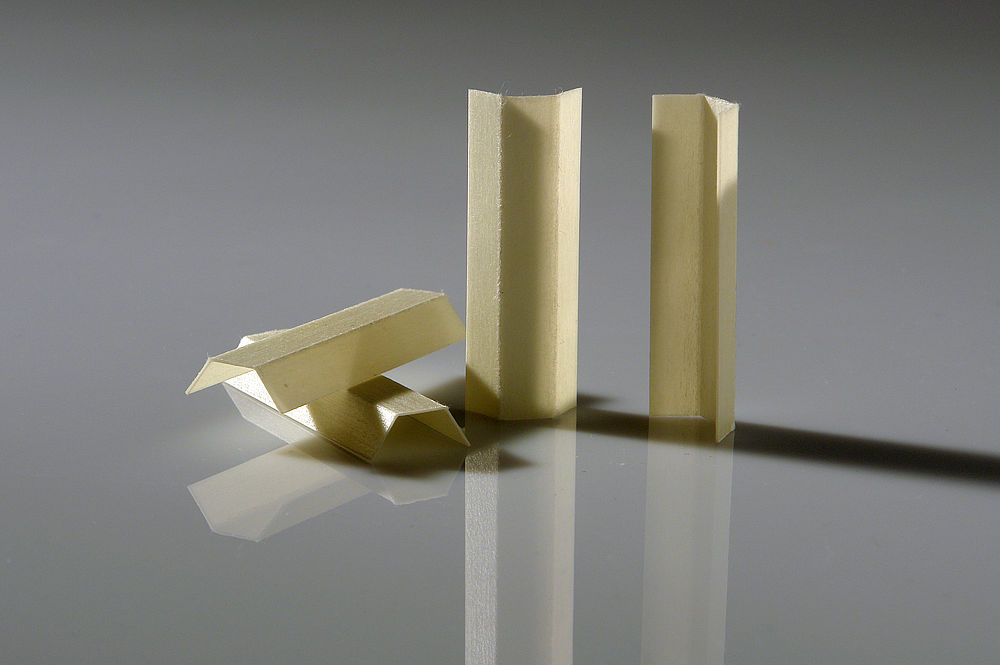

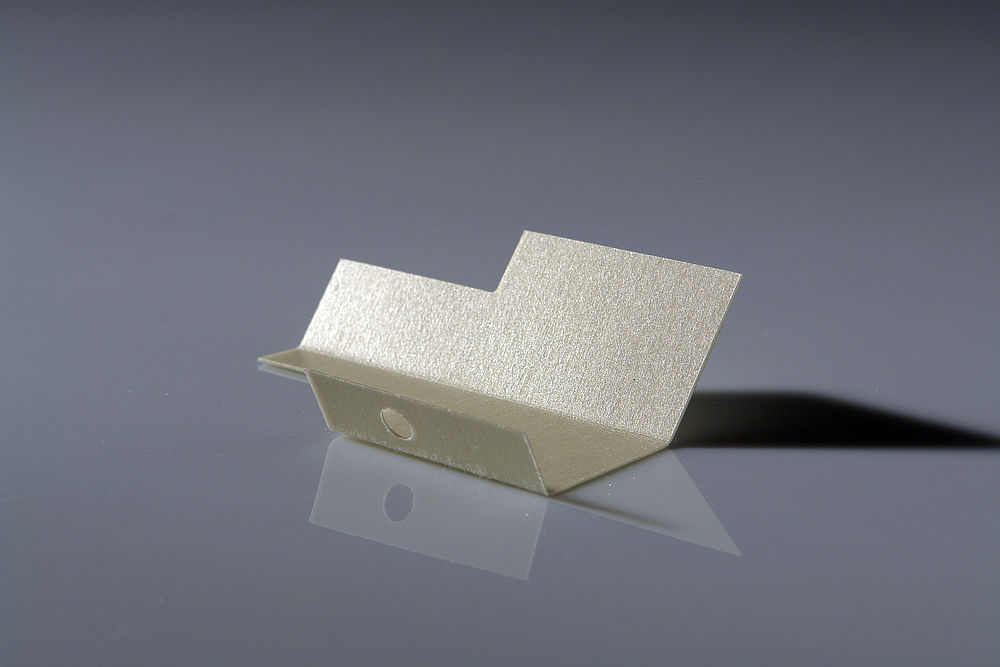

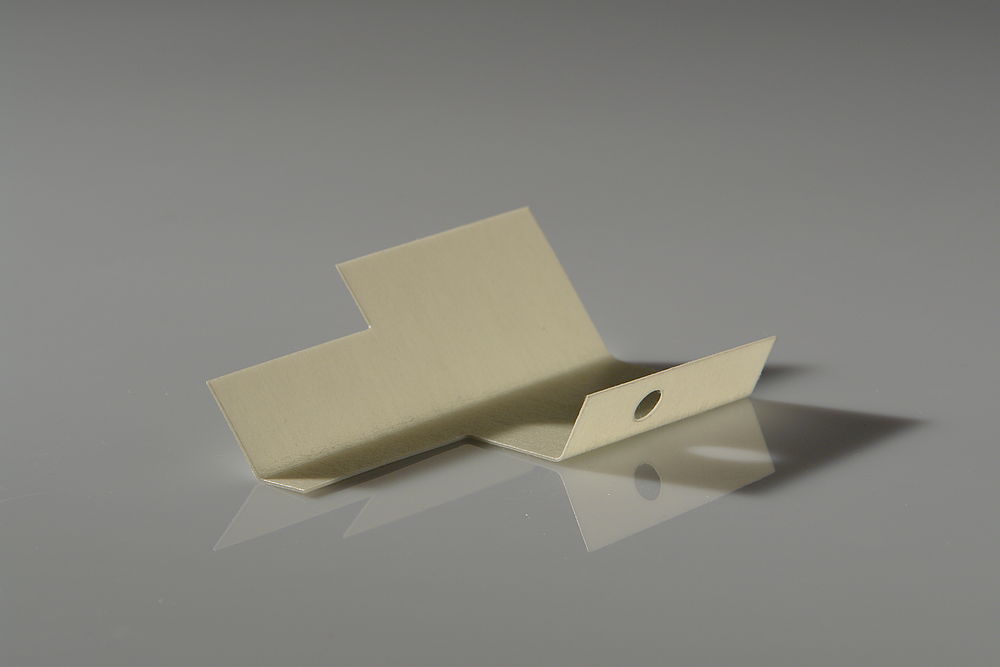

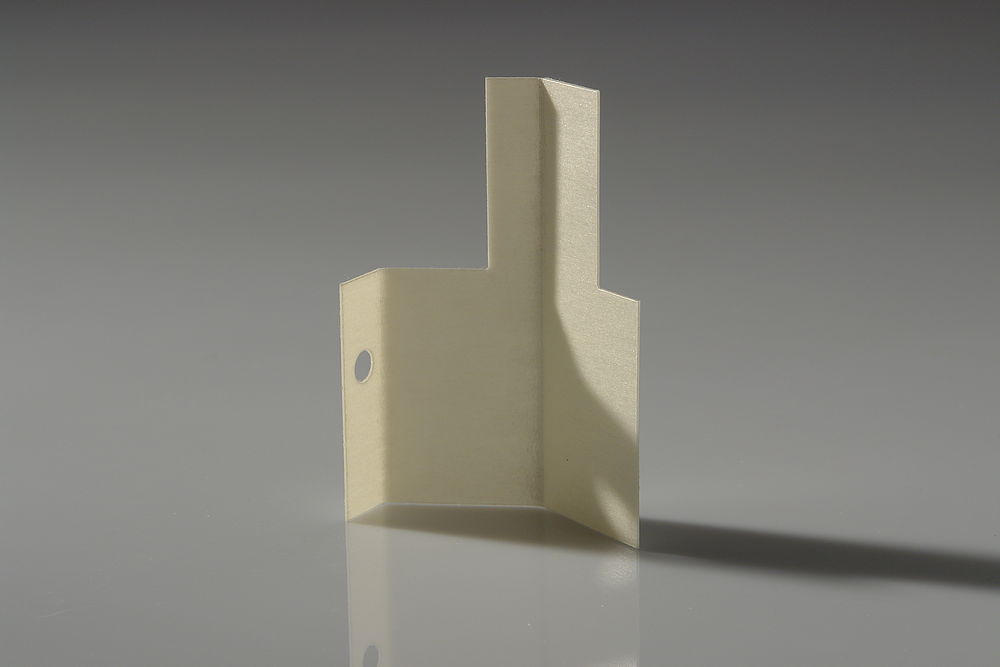

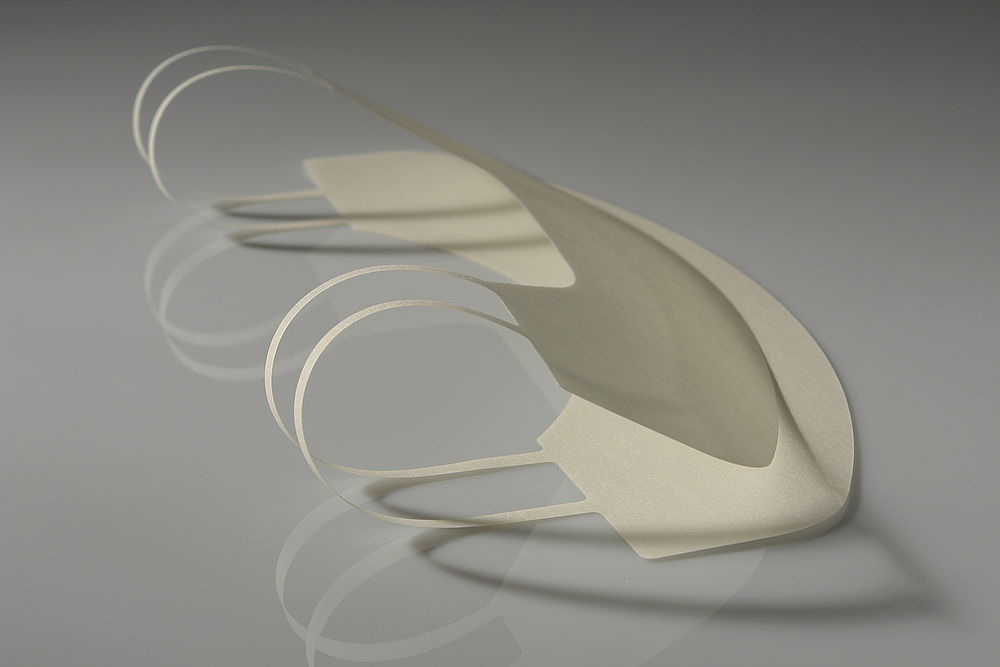

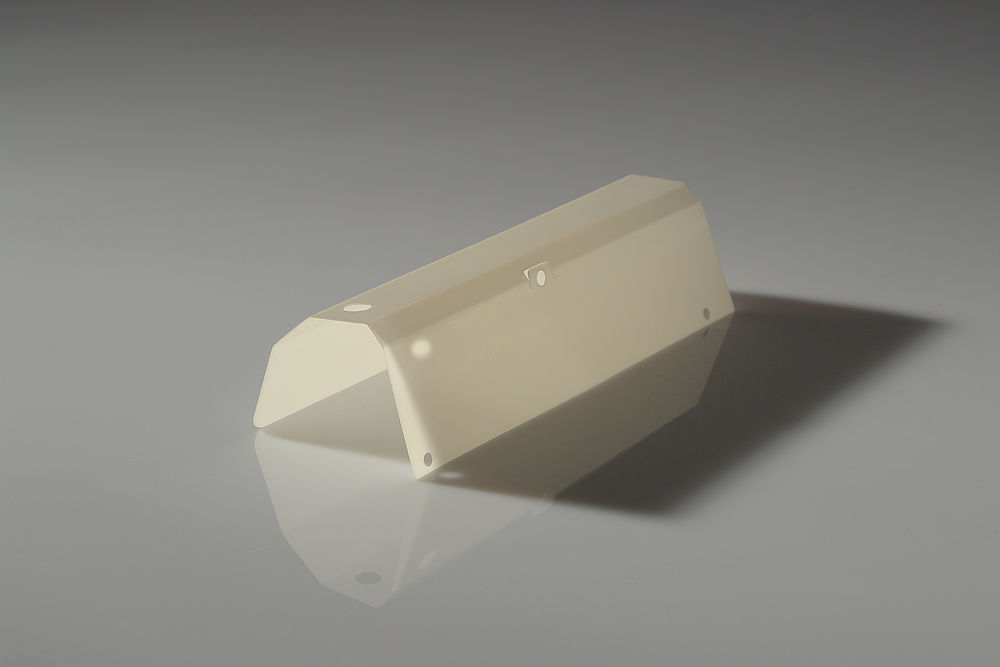

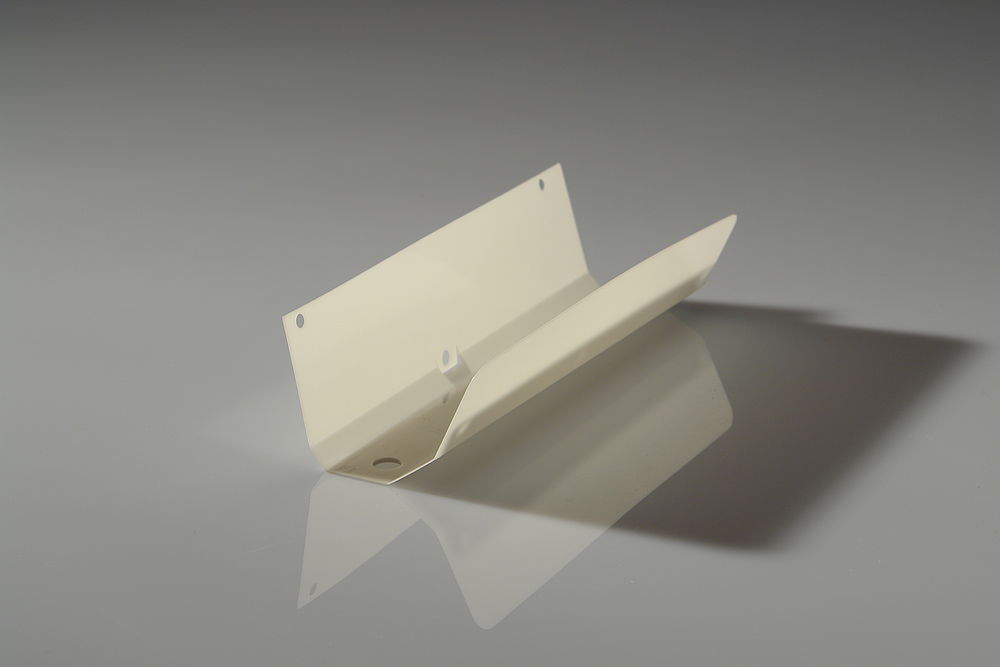

Rolls, individual parts unsorted, sorted or stacked, single and double-sided adhesive, non-adhesive, with or without grip tab.

State-of-the-art machinery combined with decades of product experience at our site in Schramberg.

Based on customized stockkeeping and tailor-made packaging solutions.

Economical production of punched parts in small and large series.

Customized, from product development to SOP.

Services for the adoption, new development and expansion of electrical insulation systems in accordance with UL 1446.

and production capacity

and sample punched parts - produced quickly and easily for you.

IATF 16949, ISO 9001

System expert for customized die-cut parts tailored to your needs

Selecting the right material is crucial to the success of your project. That is why we not only offer a wide range of well-known materials such as Nomex®, Kapton®, Mylar®, Teonex®, Hostaphan®, but also actively support you in the selection and development of specific material combinations. If the desired material is not yet available, we will work closely with you to develop customized solutions that meet your requirements. From material procurement to cutting, punching or lasering to forming, we offer you the entire vertical range of manufacture to ensure that your requirements are optimally met.

We have pooled our expertise in punched parts at our competence and production center in Schramberg in the Black Forest. Here we are able to competently implement your project on an area of more than 4,000 square meters and with employees who have decades of experience.

Joint approach

Would you like advice or to request a sample?

Thomas Lüders

Product Manager formed and punched parts

+49-171-4757-196

t.lueders@synflex.de

See our quality for yourself!

We offer you fast and uncomplicated sample production and delivery within a very short time.

Why die-cut parts are indispensable in modern production processes:

- They offer more efficient, cost-effective and uncomplicated production processes.

- Customized die-cut parts are already tailored to individual requirements.

- Thanks to their prefabricated shape, punched parts fit exactly and reduce assembly work significantly.

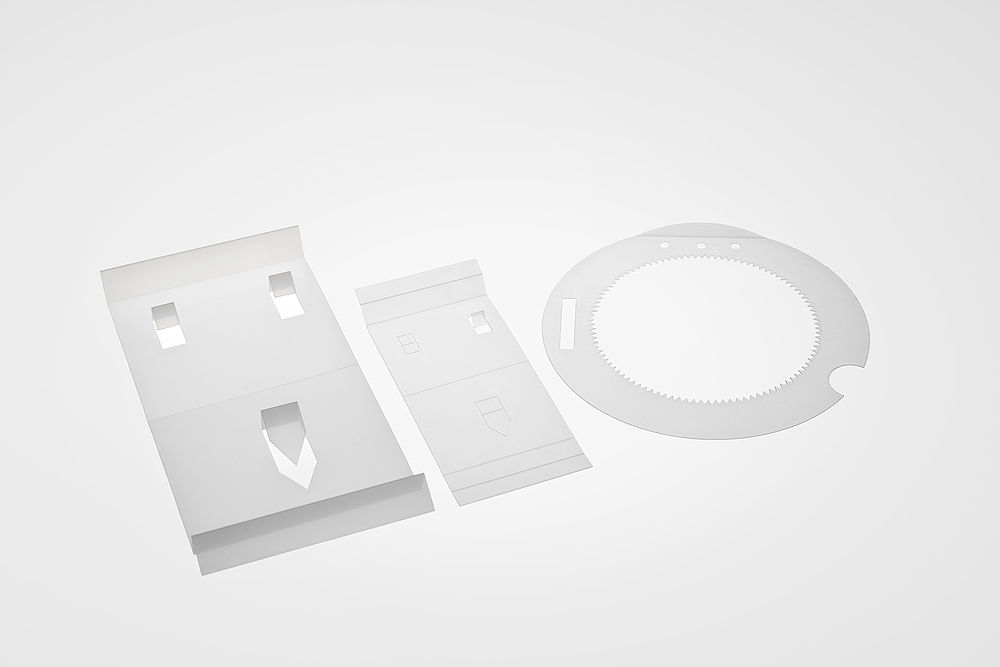

- Recesses ensure precise fixing.

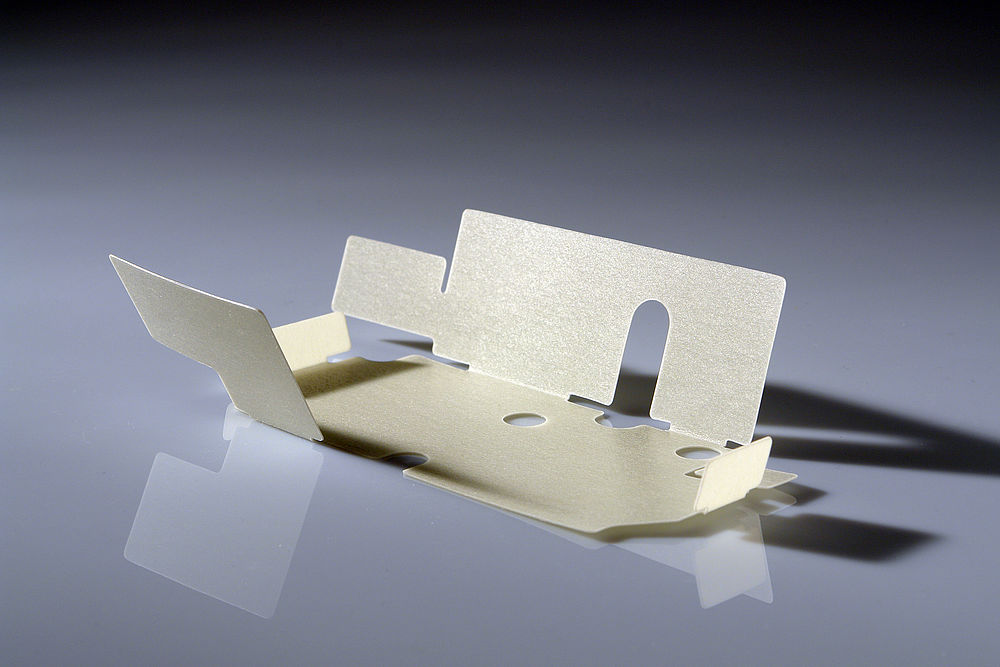

- Folds allow easy adaptation to the required geometry.

- Adhesive surfaces serve to securely fix the die-cut parts.

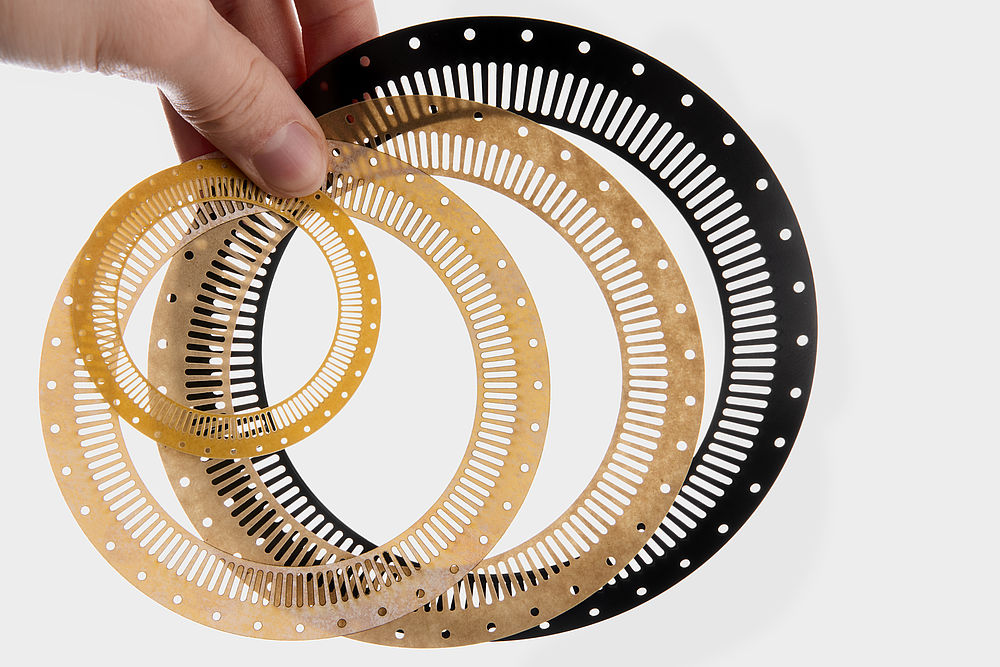

- They are used for electrical insulation in slot insulation, phase insulation, field coil insulation and armature insulation.

- They provide mechanical protection and serve to stabilize various system components.

"We have pooled our expertise at the Schramberg site. Here, my colleagues and I work hand in hand to develop practical customer solutions and guarantee the highest quality."

Thomas Lüders

Wide range of materials and high availability

We offer a wide range of punched and formed parts: Rolls, individual parts unsorted, sorted or stacked, adhesive on one or both sides, non-adhesive, with or without a grip tab. Each product is customized to your requirements - in terms of material, structure or delivery form.

SynFlex offers a wide range of material options:

- PET films (e.g. Mylar®, Hostaphan® or SynTherm® P)

- PI films (e.g. Kapton® or SynTherm® H)

- PEN films

- Aramid papers (e.g. Nomex® or SynTherm® YT510)

- Laminates made of various materials such as APA, AHA, NPN, NKN, DMD, VPV

- PMMA

- ETFE

- 3M™ FRB-NT

- Foams made of e.g. PUR

- non-woven fabrics made of polyester, for example

- fabric made of e.g. rayon staple fiber

- Pressboard

- Polycarbonate (e.g. Lexan®)

- Metals such as copper, aluminum

- Mineral materials such as mica or graphite

Numerous options for your project

- Customized punching, bending and stamping

- Bonding

- Folding

- Multi-layer coating

- Tape cutting for rolls

- Lasering

- Finishing

Tool-free sample production

Benefit from our rapid prototyping service in series production quality with which we can offer you an uncomplicated initial sampling in express service (depending on availability and production capacity). This allows you to test materials and design drafts as early as during the prototyping phase of a new development.

With our technically sophisticated and complex laser all-in-one system, our production center has cutting, marking and micro-perforating functions as well as a separate laminating and matrix stripping station. Papers, PET films, polypropylene films and Teonex® are just a few examples of materials that can be processed on the system.

Quality assurance and UL tests in our in-house test laboratory SynLab®

Our in-house test laboratory SynLab® guarantees the quality of our products for maximum reliability. SynLab® focuses on a large number of production-related and quality-monitoring tests to ensure that our products meet the highest standards. We are proud that our location in Schramberg is certified to the prestigious IATF 16949 and ISO 9001 standards, underlining our commitment to maintaining the highest quality standards.

Additionally, SynLab® is part of the UL Third Party Data Test Program. We carry out projects for our customers in accordance with UL 1446, offer you a comprehensive project service and help you to test the materials you use.

Why UL tests are so important:

UL certification according to UL 1446 is crucial for the market access of your products, especially in North America. It ensures that your electrical insulation systems fulfil the necessary safety standards and thus meet the requirements of global markets.

Our services include, among others:

- Adaptation, new development and expansion of electrical insulation systems in accordance with UL 1446.

- Comprehensive project services for the testing of materials.

- Test procedures in accordance with the UL 1446 guidelines

"Book your appointment today and let's discuss your requirements. I will be happy to advise you with my expertise."

Thomas Lüders

Graduate engineer and product manager punched and formed parts

Do you already have a sample or a drawing for die-cut parts?

Then just submit the sample, drawing, sketch or CAD graphic to us - our product manager will discuss the implementation of your individual die-cut parts with you.

You do not have exact data yet?

We will work with you to develop the right solution for your die-cut parts and blanks. We support you throughout the entire process, from the initial idea to the creation of technical drawings, sample production and the start of production of your punched parts.

Would you like to test our punched parts first?

Just ask us to manufacture a sample. Our product management team will be happy to advise you on how to successfully implement your individual punched and formed parts.

Modern machinery for the production of punched parts and blanks

Find out more about our state-of-the-art machinery which guarantees the highest quality and efficiency.

Do you still have questions or are you ready to take the first step?

Do you have any questions?

Arrange a consultation now!

Thomas Lüders

Product Manager formed and punched parts

+49-171-4757-196

t.lueders@synflex.de

Know immediately whether it fits:

We offer you fast and uncomplicated sample production and delivery within a very short time.