FiberCork – The superior thermal runaway propagation protection for battery storage systems

FiberCork and FiberCork Plus are innovative, sustainable multi-layer materials that have been specifically designed to protect battery systems from the dangers of thermal runaway. The multi-layer material stands out from existing solutions thanks to its innovative combination of materials. Cork, beech wood and glass fiber combine their individual strengths to provide superior protection:

- Cork: Lightweight and highly compressible, provides excellent thermal insulation.

- Beech wood: Robust and resistant, provides reliable protection against particle bombardment.

- Glass fiber: Supplements the layers with effective additional heat protection and ensures high mechanical resilience.

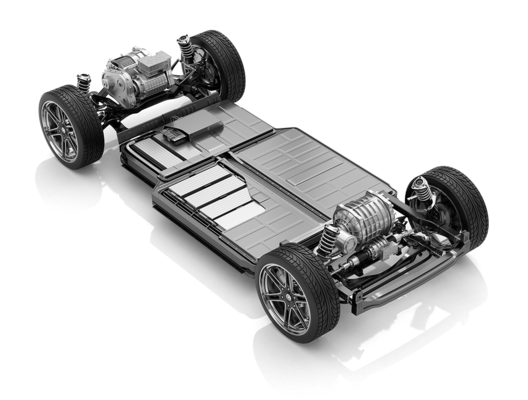

Thermal Runaway: The risk for battery systems

Thermal runaway describes the uncontrolled overheating of a battery cell. This can lead to a chain reaction known as ‘thermal propagation’. This leads to a ‘thermal runaway’ of the entire battery when the energy stored in the accumulator is released in a very short time. The consequences can be catastrophic, leading to an explosion and fire of the entire battery system. This is a serious risk, particularly for battery electric vehicles (BEV) and battery energy storage systems (BESS). FiberCork and FiberCork Plus are a sustainable alternative that impresses with its high recyclability, a European supply chain and renewable materials. At the same time, they fulfil all relevant protection requirements in terms of insulation, flame retardancy and mechanical stability.

Where is FiberCork used?

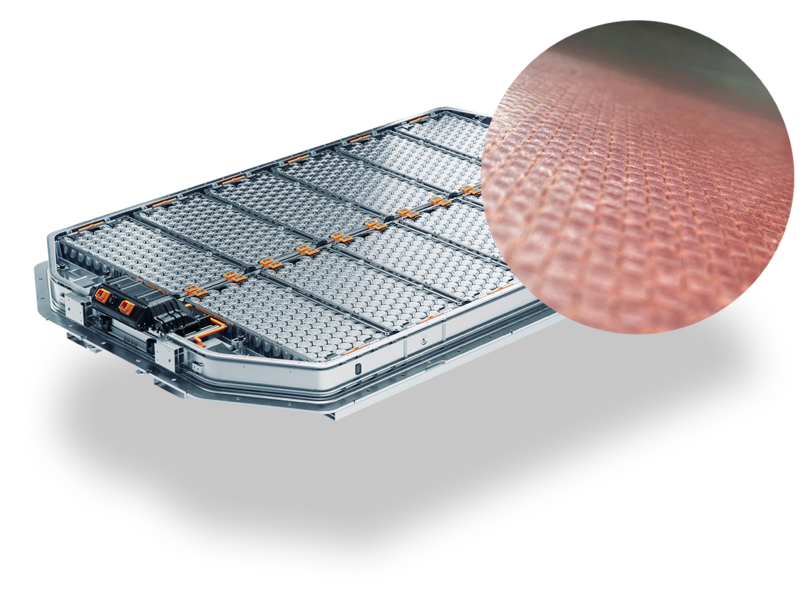

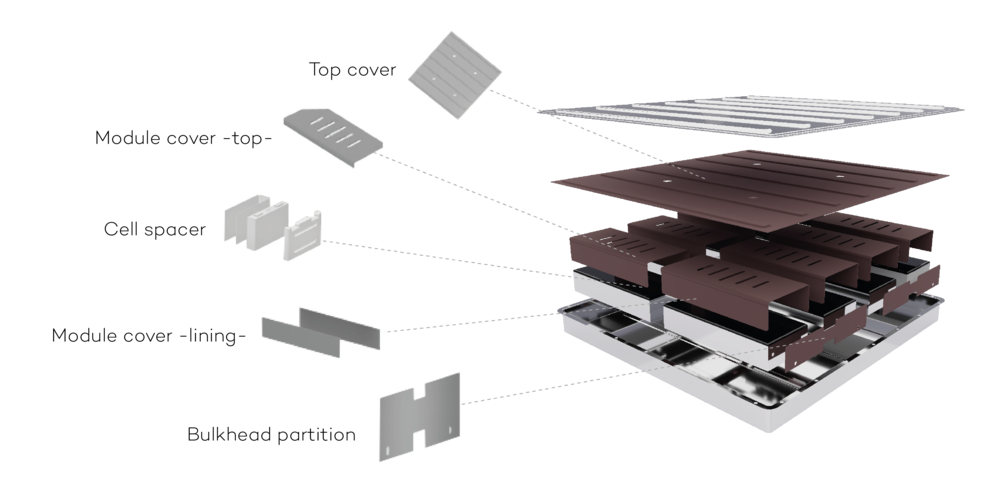

FiberCork is the sustainable choice for the thermal insulation of battery modules and battery packs. The material can be designed according to customer-specific requirements. It is produced in sheet form or as formed parts.

FiberCork benefits: Sustainability and protection redefined

- Sustainability: Over 50% renewable resources and a CO₂-negative footprint.

- Safety: Fire resistance up to 1200 °C and high resistance to particle bombardment.

- Robustness: Good mechanical strength at a low weight.

- Versatility: Can be used for cell spacers, module covers and partition walls.

- Transparency: Transparent European supply chain and CO2 footprint with environmental declaration.

What makes FiberCork superior?

Sustainability: FiberCork reduces CO₂ footprint

FiberCork is the environmentally friendly choice for battery systems. With over 50% renewable resources and a negative CO₂ footprint of up to -4.4 kg CO₂e/kg, it sets new standards for sustainability.

Cork:

- A naturally renewable raw material.

- Flame retardant - cork oak forests can even stop wildfire.

- Excellent thermal insulation due to low thermal conductivity.

Beech:

- Durable, stable and sustainable.

- Storage of CO₂ throughout the entire life cycle of the product.

- European supply chain, responsible and transparent.

FiberCork supports the objectives of the EU Battery Regulation and the Supply Chain Act by combining environmentally friendly materials with the highest technical requirements.

Safety: Maximum protection against heat and flames

FiberCork offers comprehensive protection against extreme conditions - ideal for use in battery components.

Cork as natural flame protection:

- Flame retardant for an effective fire barrier.

- Confirmed by tests with temperatures of up to 1200 °C for more than 15 minutes.

Beech for additional stability:

- Robust and resistant to mechanical stress.

- Protection against particle bombardment and electrical discharges.

FiberCork fulfils international safety standards such as UL94 and GB 38031:2020 and thus guarantees reliable protection in critical situations.

You have technical questions regarding our products FiberCork and FiberCork Plus? Contact our product manager who will be happy to help you.

Extensively tested, proven under extreme conditions

Particle bombardment test: Mechanical load capacity

FiberCork Plus shows excellent resistance to particle bombardment.

- Test setup:

- Particle bombardment with pyrotechnic stage fountains (distance 30 mm).

- Documentation of the temperature development on the back of the test sample.

- Result: No penetration of the test panel (2.9 mm thick) even after 20 seconds of intensive exposure.

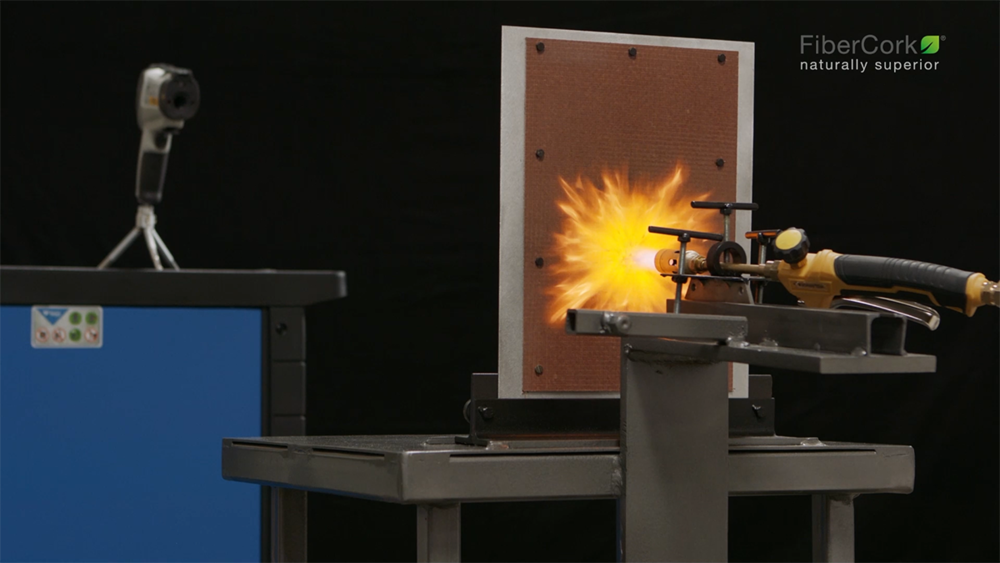

Welding-Torch Test: Fire resistance under extreme conditions

FiberCork withstands direct exposure to flames of 1200 °C for more than 15 minutes without burn-through.

- Test setup:

- Flame treatment with direct heat.

- Documentation of the results with infrared camera and JUMO temperature measurement.

- Result: No burn-through of the test panel (1.7 mm thick) even after 15 minutes.

How does FiberCork compare to other materials?

| Property | FiberCork | FiberCork Plus | Mica | Aerogel |

| Material Source | Europe | Europe | varying sources such as India | varying sources |

| Density | up to 1.5 g/cm³ | up to 1.5 g/cm³ | 2.00-2.36 g/cm³ | 0.18 g/cm³ |

| Thermal conductivity | 0.118 W/(mK) | 0.092 W/(mK) | 0.30 W/(mK) | 0.035 W/(mK) |

| Electrical conductivity | not conductive | not conductive | not conductive | not conductive |

| Protection against electrical discharges (Arc) | protection fulfilled | protection fulfilled | protection fulfilled | no data |

| Share of renewable resources | >50 % | >65 % | 0 % | 0 % |

| Recyclability | recycable | recycable | not recycable | not recycable |

| Transparent supply chain | yes | yes | no data | no data |

| Welding torch test | >15 minutes | >15 minutes | >15 minutes | no data |

| Particle bombardement test | unsuccessful | successful | unsuccessful | unsuccessful |

| OEM assembly | no restrictions | no restrictions | installation with mounting aid only | installation with mounting aid only |

| Moulding possibilities | deformation possible | deformation possible | deformation restriction | deformation possible |

How FiberCork is shaping the future of sustainable battery systems

FiberCork not only meets the increasing requirements for sustainable thermal protection, but also sets new standards in the battery industry by combining environmental responsibility with technical performance.

1. Transparent CO₂ footprint

FiberCork is a climate-friendly solution with a negative CO₂ footprint of up to -4.4 kg CO₂e/kg, which is well below the values of conventional materials, which has a positive footprint of +8.5 kg CO₂e/kg.

2. Fulfilment of recycling requirements

- FiberCork is recyclable in accordance with the requirements of the EU Waste Wood Ordinance.

- It supports the targets of the EU Battery Regulation which stipulates a recycling rate of 65% by 2025 and a rate of 70% by 2030 for the weight of lithium-ion batteries.

3. Compliance with the Supply Chain Act

FiberCork guarantees a transparent and responsible supply chain.

- All raw materials come from Europe and are sourced in compliance with high social and environmental standards.

With FiberCork, you are not only opting for a high-performance solution, but also for one that actively contributes to the decarbonization of modern energy systems and significantly reduces the environmental impact.